Engineered Wood, also known as composite wood, is a category of building materials that consist of wood-based products made from various types of fibers and veneers, along with adhesives. These materials are designed to provide improved strength, stability, and dimensional accuracy compared to traditional solid wood.

Engineered wood is made by bonding together thin layers of wood veneers, fibers, or particles using adhesives. This process results in a material that is stronger and more uniform than solid wood, making it ideal for use in construction and building applications.

RF Specialties works with several different types of engineered wood products. These materials are commonly used in applications such as:

Adhesives play a critical role in manufacturing of engineered wood products, as they are used to bond the fibers, particles, or veneers together. The strength and quality of the adhesive used will directly impact the final performance of the engineered wood product. Additionally, adhesives can be specially formulated to provide resistance to moisture, heat, and other environmental factors, helping to extend the lifespan of engineered wood products.

Engineered Wood is a versatile and sustainable alternative to solid wood that offers improved performance, strength, and stability. It is widely used in a range of construction and building applications, and adhesives play a critical role in its production and performance.

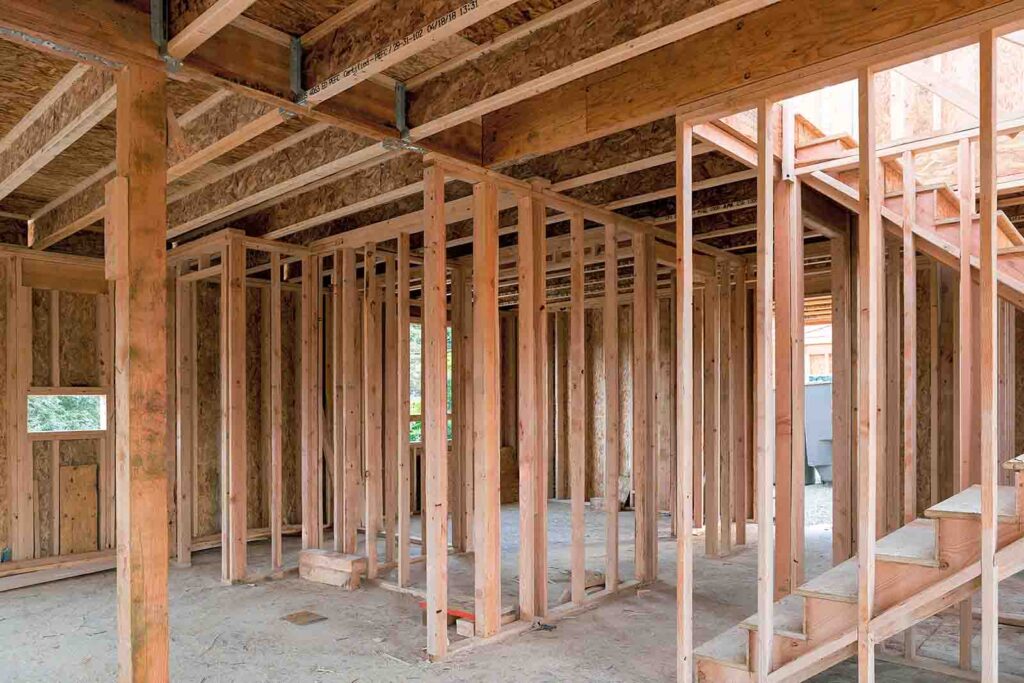

Structural wood refers to engineered lumber products that are used in construction and building. They are made by bonding together smaller pieces of wood, known as veneers, with adhesives to form larger, more solid pieces. This process increases the strength, stability, and durability of the final product.

Some common examples of structural wood include laminated lumber (CLT), finger jointed lumber (FJL), and glue-laminated timber (GluLam). These materials are used in various construction applications, including:

Adhesives play a critical role in the manufacturing of structural wood products. The type and quality of adhesive used can have a significant impact on the final product. Adhesives can also provide resistance to moisture and decay, helping to extend the lifespan of structural wood.

RF Specialties enhances manufacturers ability to provide structural wood. Allowing for a strong, durable, and sustainable alternative to traditional lumber for many construction applications

RF Specialties provides a wide range of consulting services surrounding the adhesives space. We have a long history of matching adhesive technology with customer needs. This includes formulation of specialty adhesives for RF compatibility, allowing companies to leverage the benefits of RF technologies into their manufacturing process.

Keith Mort’s infamous “Glue School” has been taught around the country to manufacturing organizations. We can educate teams, advise on projects, or create custom manufacturing solutions tailored to your specific problem.

Radio frequency pasteurization, disinfestation process is a non-thermal food processing technique that uses high-frequency electromagnetic energy to kill harmful microorganisms in dry food commodities. The RF treatment process exposes food products to high energy waves which generate heat within the product. This internal heating causes the temperature to rise, killing harmful pathogens and disinfecting, and resulting in the highest standards of food safety. In our disinfestation process we are able to perform log kill reduction, meaning that with every step, the number of bacteria present is reduced by 90 percent.

This process can be fast and efficient, while preserving the taste and nutrition of the food. Our process is fast, efficient, and performed at low temperatures, preserving the authentic taste, aroma, and nutritional value of the food. From spices and dried fruits to flour, our RF pasteurization technology is setting new standards for food safety and quality for the dry food industry.